More integration of components: The story behind AISIN's "X-in-1" eAxle [5-minute read]

Mar.15, 2024

Vehicle electrification is rapidly advancing around the world as an efforts to achieve carbon neutrality increase. Under such circumstances, an eAxle, a new drive unit for battery electric vehicles (BEVs), is attracting attention as a component that can replace the conventional engine and transmission. With various companies working on eAxle development, AISIN’s “X-in-1” appears to be a legitimate advancement of the future of eAxle development.

What is an X-in-1 eAxle?

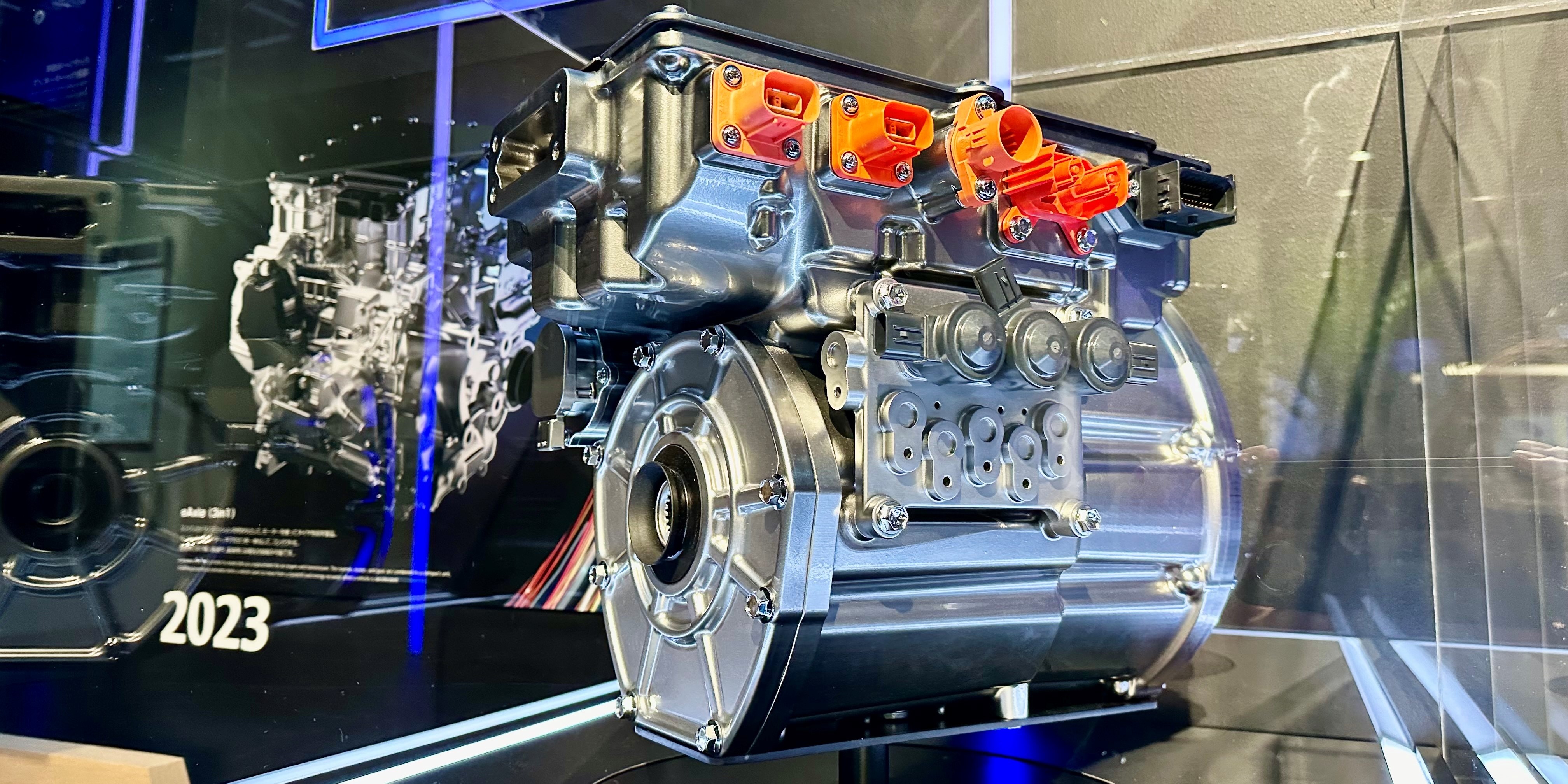

“X-in-1” is the generic term for an eAxle that combines multiple components or functions into one, where “X” indicates the number of integrated components. For example, when five components are integrated, it is called a “5-in-1” eAxle; when eight components are integrated, it’s an “8-in-1” eAxle, and so on.

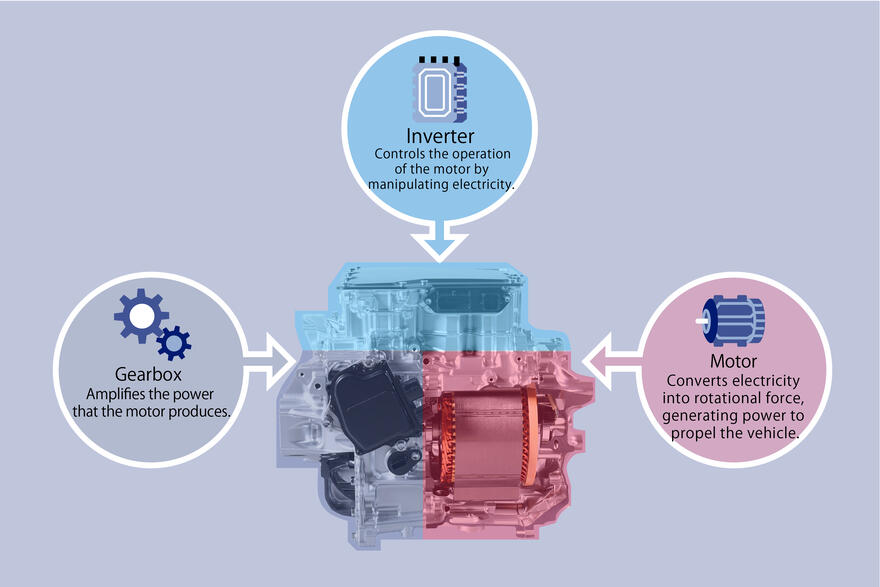

The current mainstream eAxle is a combination of inverter, gearbox and motor. This is called a “3-in-1” eAxle.

The integration of electric drive units is expected to increase, and various companies are working to develop an “X-in-1” eAxle, which combines more components into one.

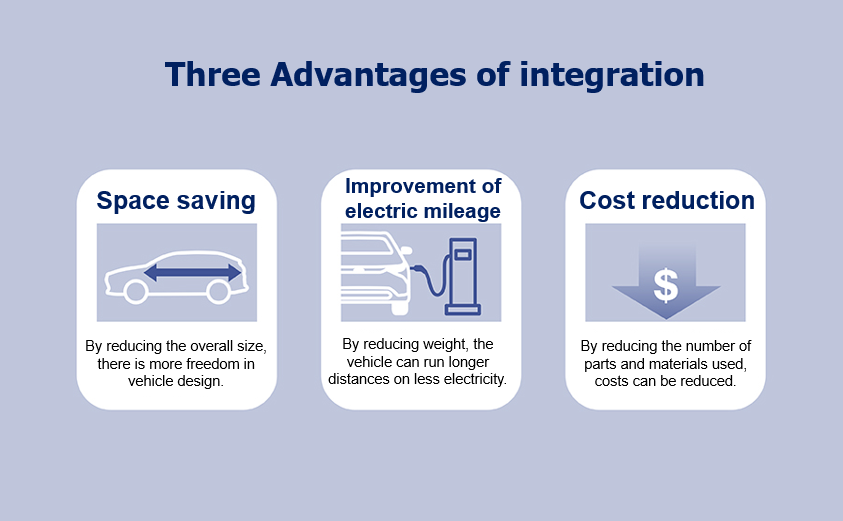

Advantages of integrating multiple components

By integrating multiple components – individual cases, cables connecting components, and piping – are no longer needed, enabling reduction of the overall size. As a result, the degree of freedom in vehicle design can be increased, allowing for more space in the trunk and inside the vehicle.

Next, by reducing the size, vehicle weight is also reduced, which allows it to run longer distances while using less power. This means electric mileage of electric vehicles can be improved.

Also, by using fewer parts and less material, costs can be reduced. While high vehicle costs are currently an issue impacting the widespread use of electric vehicles, reducing costs of the eAxle and other key units can help lower overall EV costs.

By integrating more components, the overall size and weight of vehicles can be reduced, creating the effects of space saving, improved electric mileage, and lower costs.

Aisin’s “X-in-1”

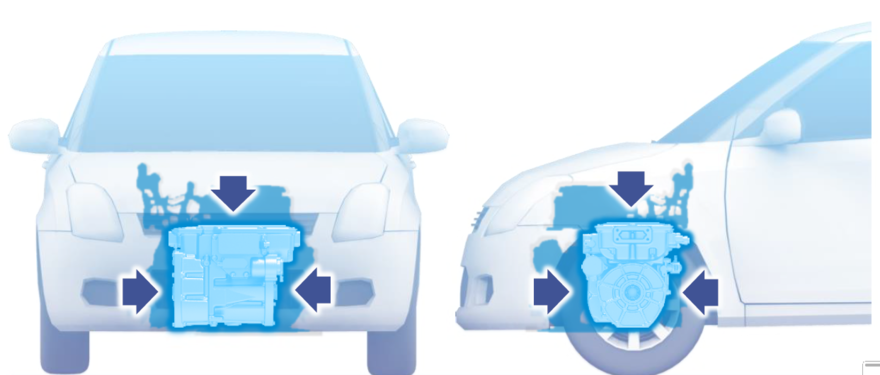

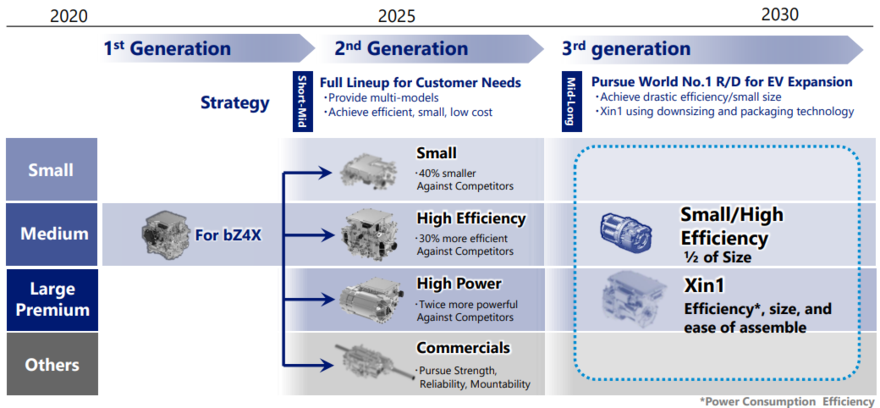

Aisin is developing a 3-in-1 eAxle based on a three-generation concept. The first-generation eAxle has already been mass-produced and is used in Toyota’s bZ4X and other electric vehicles. We aim to achieve the world’s highest level of efficiency in the second-generation eAxle, which is scheduled to be introduced in 2025 to help strengthen a full product lineup. The third-generation eAxle is aimed at achieving overwhelming miniaturization, reducing the overall size by 50 percent of the first generation.

As one of the possibilities beyond that, AISIN is developing a new product, the X-in-1 eAxle, which will integrate even more components.

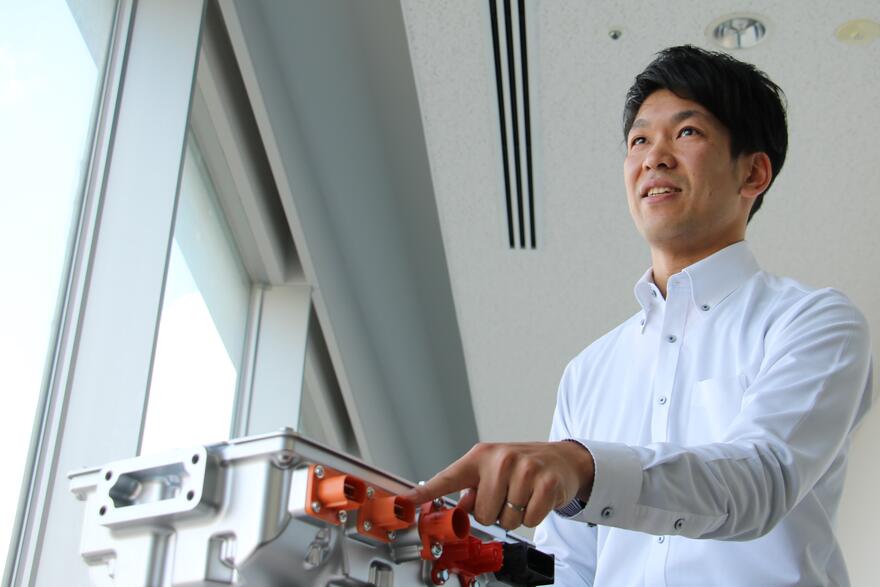

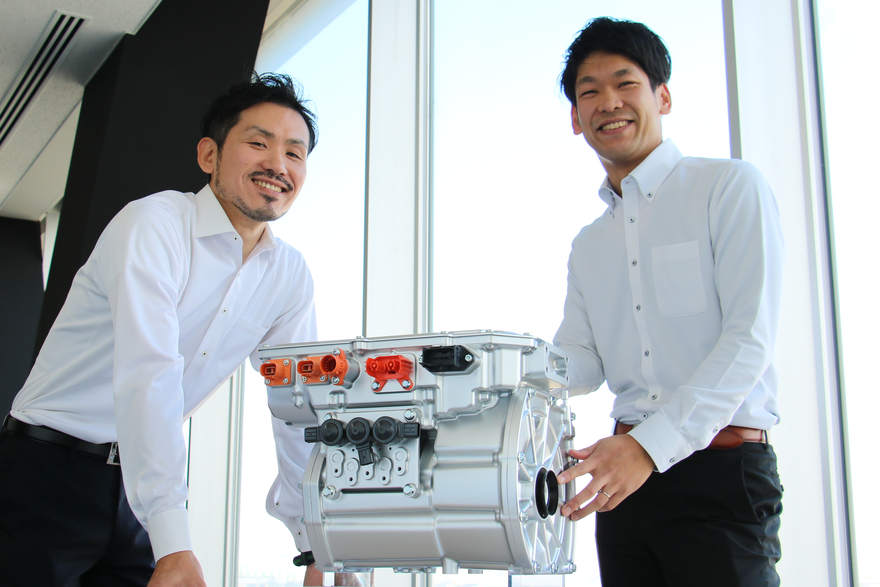

Takuyo Maeda, who is leading the project, explains the X-in-1.

“Aisin’s X-in-1 eAxle features the integration of a power converter, thermal management system, and integrated control function, in addition to components in the conventional 3-in-1, says Maeda. “The overall size reduction of the third generation by 50-percent is innovative enough, but by integrating even more components, the space under the hood can be increased significantly. This allows for greater freedom in vehicle design and provides benefits such as a larger trunk compartment. In addition, much more space inside the vehicle will also change the way people spend time in vehicles. We also emphasized entertainment and other elements, integrating the power system. We will create new mobility value, considering all possibilities, such as ease of getting in and out of the vehicle.”

Unrivaled strengths

Maeda says that the overwhelming miniaturization of the eAxle is made possible by AISIN’s strength in being able to develop products from the material stage up.

“For example, we have reduced the width of the gears by half by using strong materials for the steel used in the gears. This is only possible because of our knowledge of steel composition and processing. In terms of elemental technology, too, our competitors are absolutely no match for us,” adds Maeda.

Furthermore, Hiromitsu Kuboyama, who leads the development of the second generation, explains why the world’s highest level of efficiency can be achieved as follows.

“AISIN has a history of more than half a century of pursuing ‘high efficiency and miniaturization’ in transmission development,” says Kuboyama. “We have built up technologies to make each component smaller and more efficient. This is possible because we develop many functional components in-house.”

Further added value through integrated vehicle control

Kuboyama says AISIN’s X-in-1 eAxle will also have the integrated control function of vehicle motion.

“We offer a wide range of products related to vehicle functions, such as driving, turning, and stopping. By linking and coordinating the eAxle with these products, we can improve safety, power efficiency, as well as driving pleasure and comfort.

“For example, electric vehicles have the weakness of being vulnerable in cold weather. Since a cold battery is hard to power, it needs to be warmed up. Likewise, the interior of the vehicle also needs to be heated. But since heating requires a lot of energy, the heat generated from the eAxle is used as warm air, and when that is not enough, electricity is used to increase the eAxle’s heat output. When too much electricity is used at this time, the distance that the car can travel is reduced.

“Therefore, the system uses the route search and location information from the vehicle navigation system to determine the need to warm up the battery and the vehicle interior for the upcoming driving route. If the remaining distance to the destination is short, the vehicle can be driven without warming up to conserve electricity. We can not only improve the attractiveness of the product itself but also create high added value for the vehicle because we are well versed in vehicle manufacturing,” says Maeda.

Kuboyama adds: “We are committed to meeting the various needs of regions around the world by offering a full lineup of products, not limited to only the X-in-1 eAxle. We will continue to offer new user experiences to everyone, so please look out for them!”