Continuous energy-saving improvement technologies at plants helps to achieve carbon neutrality

~ Aisin’s initiative to reduce CO₂ emissions of aluminum melting furnaces ~

Apr.20, 2022

Aisin is working hard to help create a society where everyone can live with peace of mind in harmony with nature, and achieving carbon neutrality is a key factor in reaching that goal. We are working to reduce our CO2 emissions by 50% by 2030 and achieve carbon neutrality by 2050 through initiatives focused on both “production” and “products.”

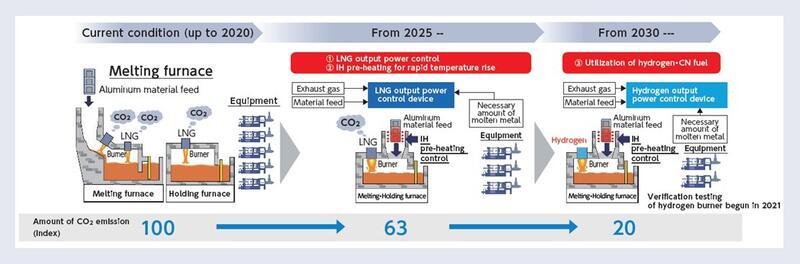

In production, melting processes such as die casting, melting furnaces and heat treating account for about 30% of the total CO2 emissions from Aisin’s plants in Japan. We believe that reducing CO2 emissions in these processes will lead to significant results in achieving carbon neutrality.

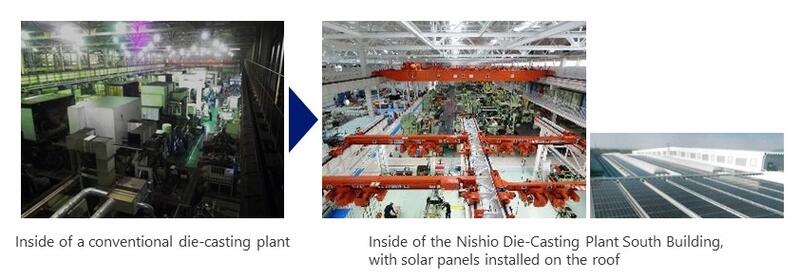

Overcoming the stigma of the hot, dark die-casting plant

What comes to mind when you think of a die-casting plant?

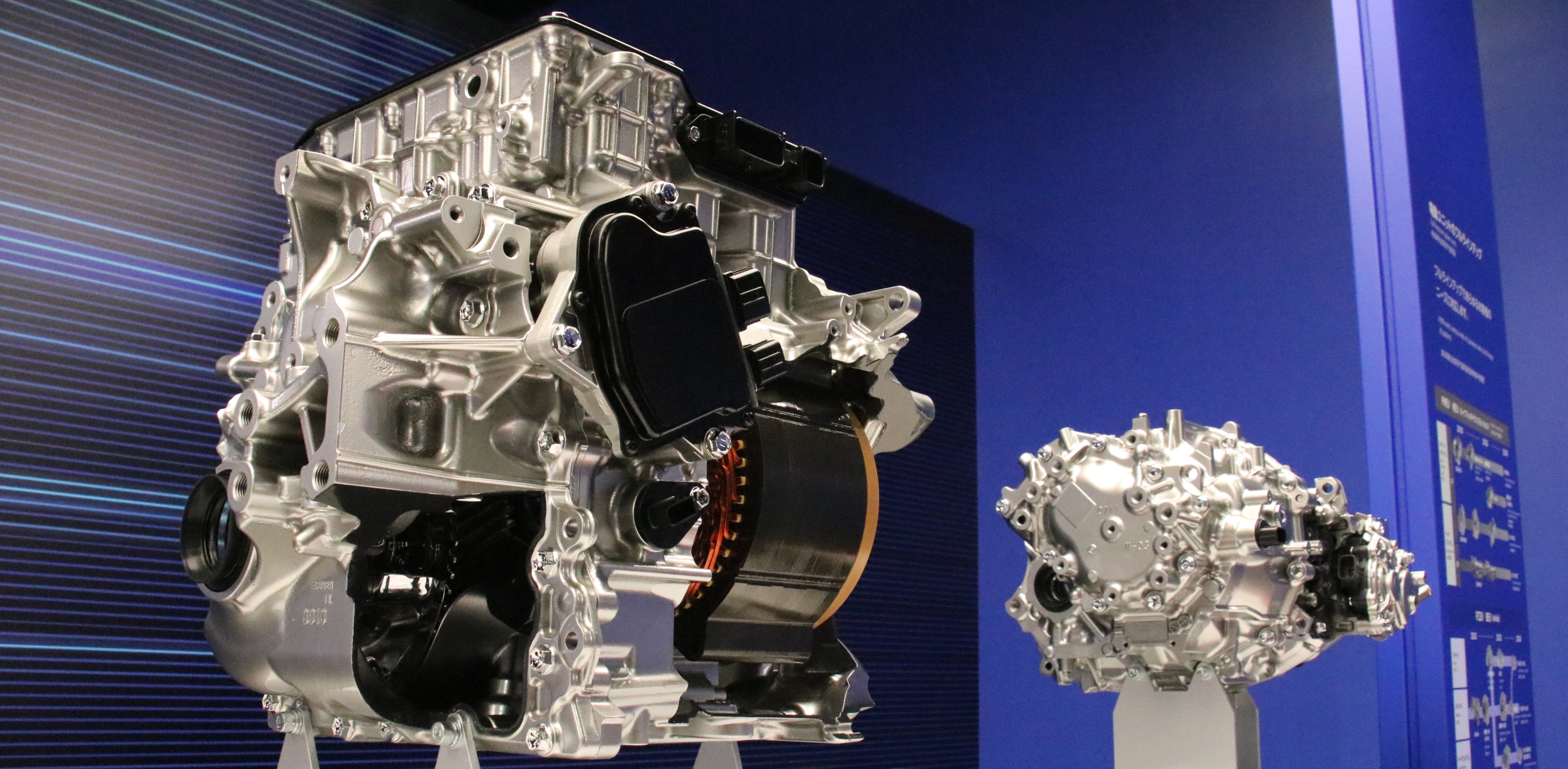

Die casting is a method of mass-producing molded products with high dimensional accuracy and at high speed by feeding molten aluminum or other metals into dies under high pressure. Aisin has employed this method to cast electric unit cases for electric vehicles and hybrid vehicles.

Since these processes involve high-heat processing to melt metal and require large pieces of equipment, you may envision the inside of such a plant being very hot and dark. This is certainly true for Aisin’s conventional die-casting plants.

However, the Nishio Die-Casting Plant South Building, which started operation in 2018, features a work floor with natural light from the ceiling, thermal insulation and good ventilation as well as a white-colored interior, thereby creating a work environment that defies stigma. In addition, the plant uses renewable energy by installing solar panels with a power generation capacity of about 1,000 kW on the roof.

Reducing CO2 emissions with technology to control burner combustion efficiency

Aluminum melting furnace (left) and molten aluminum holding furnace

In the melting furnace, aluminum ingots are melted with a gas burner. In this process, the temperature of the exhaust gas in the furnace is controlled by turning off the output of the burner as the temperature rises above 600℃. The conventional melting furnace was only capable of turning the burner’s output on or off (zero or 100%). So in order to melt smaller batches of aluminum, the furnace had to still be fully heated repeatedly, wasting much energy.

The melting furnaces newly installed in the Nishio Die-Casting Plant South Building enable the burner’s output to be flexibly controlled between 25% and 100%. The new melting furnaces curb the generation of wasted energy by monitoring and controlling the temperature inside the furnace and the flow of aluminum, thereby improving the melt efficiency. This new control technology has already been deployed to all seven furnaces of the Nishio Die-Casting Plant South Building. In fiscal year 2020, CO2 emissions were reduced by 15% from fiscal year 2018.

The technology to eliminate wasted energy is essential regardless of the power source(s) used in the future. Aisin will further enhance the technology and push forward with its deployment of furnaces to other plants.

We will not loosen the reins in our efforts to develop new, environmentally-friendly technologies and put them into practical use.

By 2025, we aim to reduce CO2 emissions by 37% (from fiscal year 2018) by preheating aluminum with electric energy to reduce the use of gas burners and by integrating the two stages of using a melting furnace and a holding furnace.

In addition, with a view to future use of hydrogen and CN fuel, we are now conducting demonstration experiments.

Mr. Ukai from the Light Metal Production Engineering Department expresses enthusiasm for pushing forward with the project:

“The hurdles are high for reducing CO2 emissions. For the practical use of new technologies, we must continue to develop technology with less initial investment and more efficiency improvement. We will make continued efforts to overcome these obstacles in order to ‘create tomorrow.’”

Aisin will further accelerate its initiatives to achieve carbon neutrality in terms of both “production” and “products.”