Logistics Innovations That Benefit People and the Planet. What is Aisin's DX-L? [Part 1]

May.25, 2022

![Logistics Innovations That Benefit People and the Planet. What is Aisin's DX-L? [Part 1]](/en/aithink/assets_c/2022/06/Aisin_logistics_DX_main-thumb-4838x2396-7221.jpg)

To quickly respond to diversifying market needs while addressing social issues, such as helping realize a carbon-neutral society, Aisin is actively promoting digital transformation (DX) of manufacturing, including shortening development periods and improving production efficiency.

To further advance our initiatives, we are focusing on the utilization of digital technology in the logistics field, and this two-part article explains Aisin’s initiatives.

What is DX-L?

DX-L is the abbreviation of the term "DX-Logistics," more specifically, Aisin’s initiative to resolve issues and create new value by innovating logistics through DX.

DX-L has two major components: To contribute to global environmental sustainability and to reduce the burden on workers.

Global environmental sustainability.

To create a society where everyone can live with peace of mind in harmony with nature, we are simultaneously accelerating our efforts to achieve carbon neutrality in the production phase while also providing electrified and other eco-friendly products.

Logistics, the support infrastructure for manufacturing, is also a target field of our efforts. We will reduce CO2 emitted during transportation while helping increase the competitiveness of products through highly efficient and low-cost logistics.

Reducing the burden on workers.

Logistics is a yet-to-be-digitized field in which many transportation-related and management tasks are still carried out manually. These additional tasks add to an extensive list of heavy burdens facing these workers, and their long working hours are recognized as a social issue.

DX-L aims to realize human-friendly logistics that is easy to use, fully digital and can reduce the burden on workers.

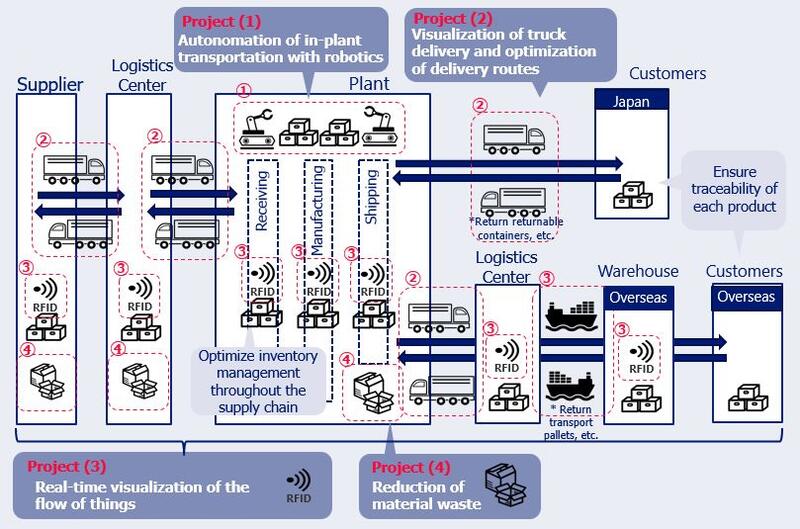

In the DX-L initiative, efforts are being made under various themes.

This series of articles, Part 1 and Part 2, introduces four DX-L projects.

Part 1 covers Project (1): Autonomation of in-plant transportation with robotics, and Project (2): Visualization of truck delivery and optimization of delivery routes.

Project (1): Autonomation of in-plant transportation with robotics

While optimizing logistics, Aisin is working toward the autonomation of on-site logistics with robotics to reduce the burdens on workers and improve productivity.

In Japan alone, Aisin Corporation has about 6,000 workers engaged in on-site logistics to support manufacturing.

Logistics operations include many simple tasks and manual labor jobs. The autonomation of such jobs can help improve the working environment and reassign the personnel working there to higher value-added jobs. This, we believe, is important to achieve both stable product supply and the happiness of workers.

Automating transportation with AGVs and AMRs

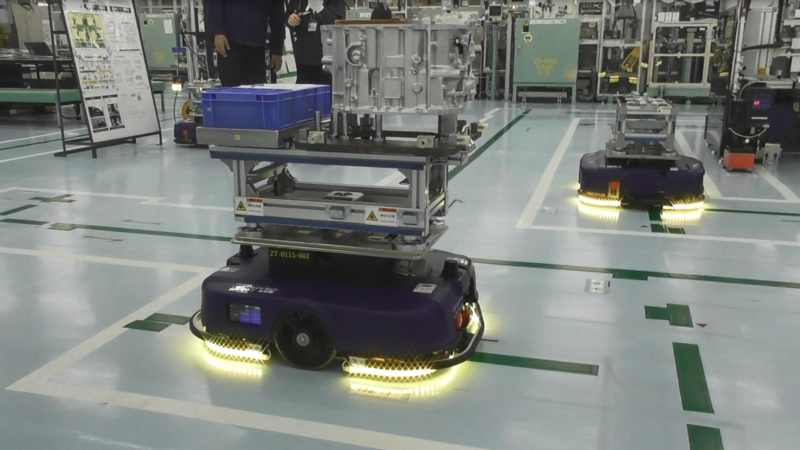

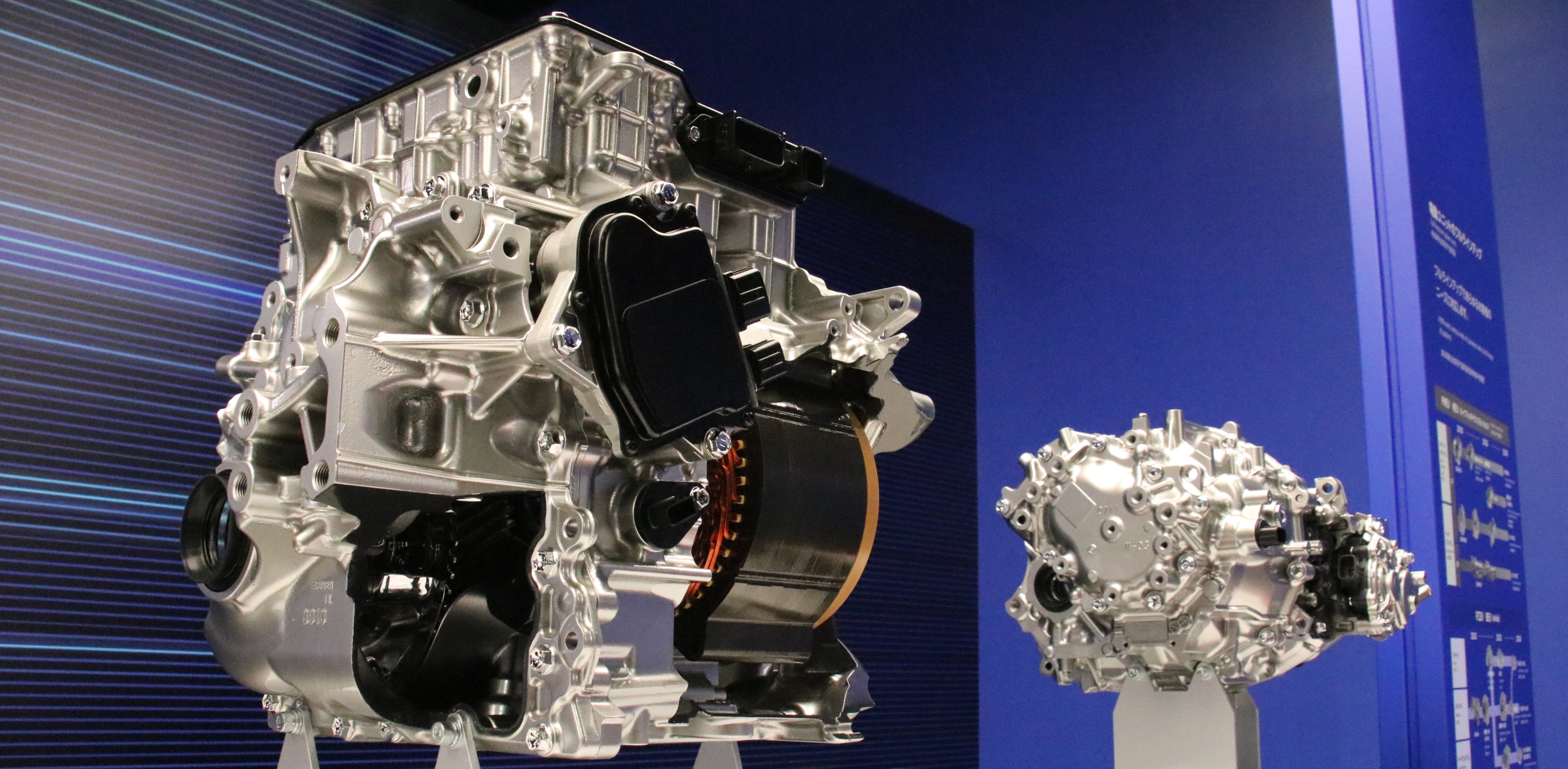

We are currently working on the introduction of transfer robots, including automatic guided vehicles (AGVs) and autonomous mobile robots (AMRs).

An AGV is a robot that runs autonomously along magnetic tape or other marked lines on the floor and carries items weighing up to 600 kilograms.

The AGVs in the image below, which were developed in-house, have already been put into practical use in some of our plants.

To take autonomation one step further, we are also developing an AMR that enables autonomous driving without guidelines. Unlike AGVs, AMRs can move around the plant freely, thereby flexibly responding to changes in the surroundings, including layout changes and obstacles. They also bring about other advantages: they do not require guideline installation or environmental maintenance, allowing preparation periods to be shortened.

High costs and difficulty in setting up the system inhibit the introduction of AGVs and AMRs. To address such issues, Aisin aims to significantly reduce costs by utilizing its own technologies including vehicle design and autonomous driving, and its own products such as motors. In addition, Aisin is also developing software for controlling AGVs and AMRs with the aim of realizing an easy-to-use transportation system available to everyone.

In the future, we plan to develop world-class AMRs by evolving them into logistics robots that handle on-site transportation in combination with picking, and installing AI systems in AMRs to enable them to transport items with human dexterity. Such AMRs can only be developed by us, as we have an unparalleled depth of understanding of the manufacturing site. Through these initiatives, we will help achieve unmanned logistics operations for our company and for society as a whole.

We will also actively utilize robotics in various situations outside of AGVs and AMRs to promote the autonomation and unmanned operations of on-site logistics. By 2030, we aim to dramatically increase productivity by reassigning about half of the personnel involved in logistics and other production to higher value-added jobs.

Project (2): Visualization of truck delivery and optimization of delivery routes—Addressing the formidable challenge of optimal route planning to cut CO2 emissions in half.

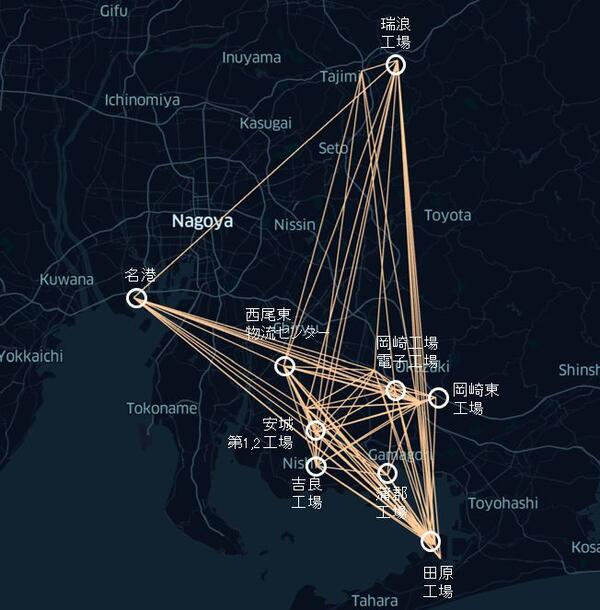

For Aisin Corporation’s daily business operations in Japan, roughly 900 trucks run on nearly 500 routes.

As a result, annual CO2 emissions amount to approximately 573,000 tons.

The reduction of the number of trucks through improved delivery efficiency will help reduce CO2 emissions and greatly contribute to the realization of carbon neutrality. Furthermore, it will also be helpful in reducing the burdens on drivers and resolving other issues in the logistics industry.

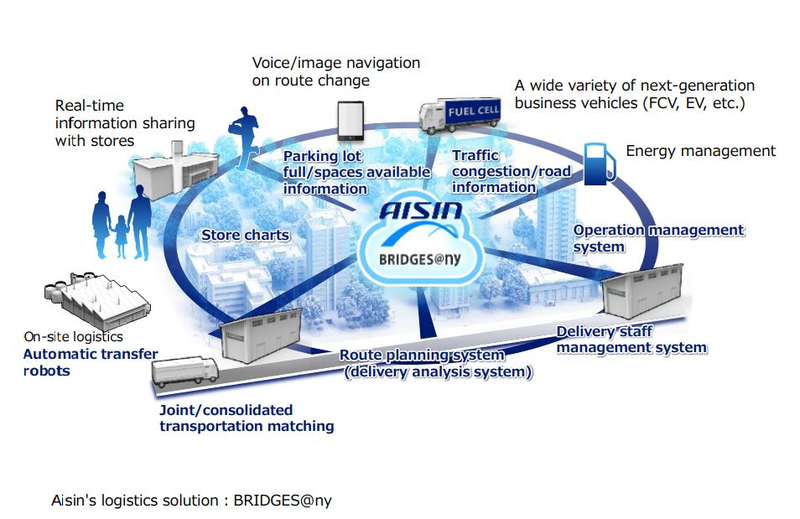

Bridges@ny visualizes full information on truck delivery

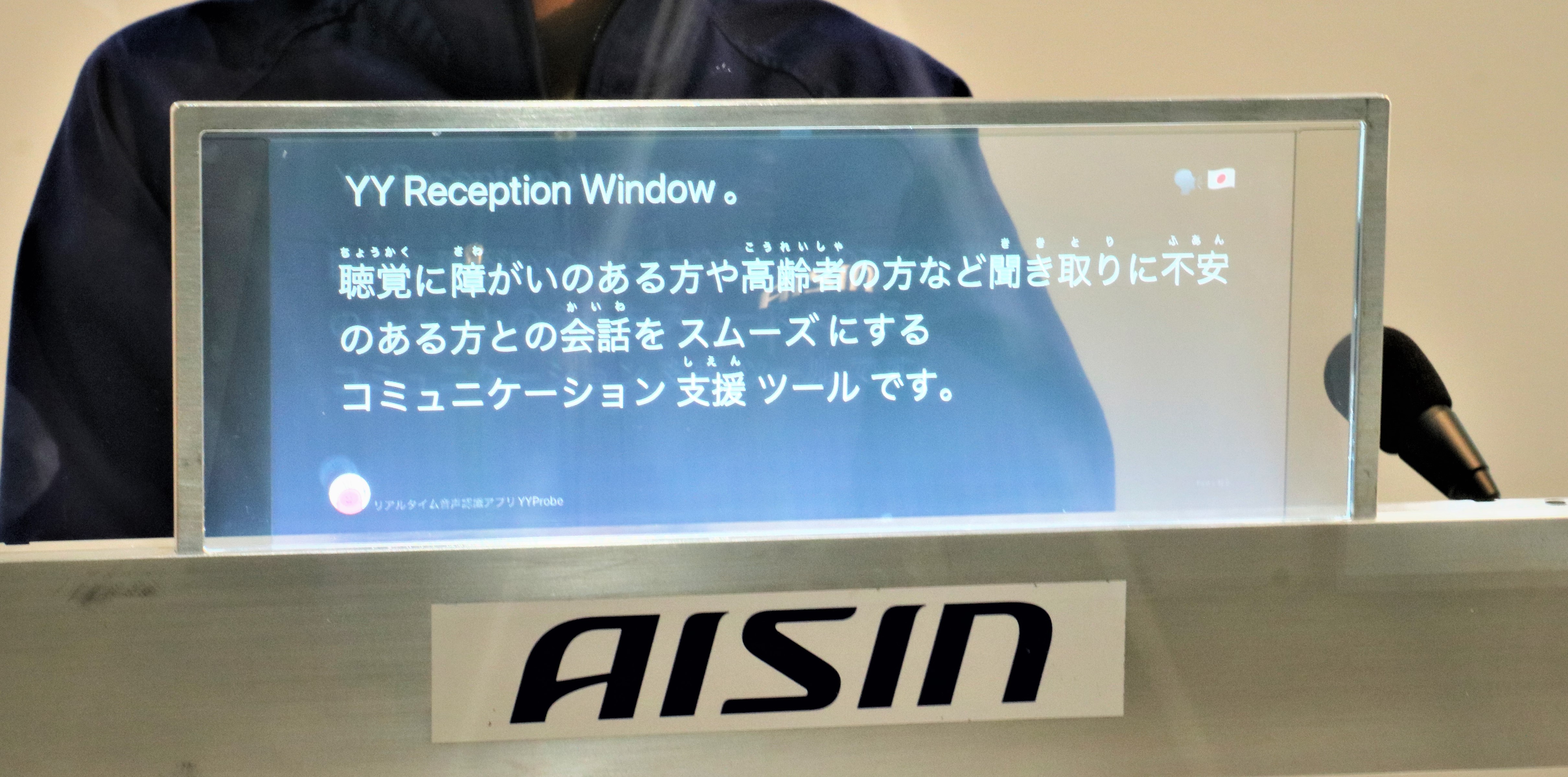

As an effective means of streamlining truck delivery, the logistics optimization service "Bridges@ny" has become the focus of our attention.

Bridges@ny is a logistics support service developed and provided by Aisin based on the location-aware technology that the company has cultivated in its car navigation business.

Bridges@ny optimizes the entire logistics value chain from various angles by, for example, proposing a highly efficient delivery plan devised using a unique algorithm, and providing a real-time tracking management service that grasps the locations of delivery trucks en route by using GPS.

Previously, truck delivery management used to require calling the driver to check the current location and formulating delivery plans based on experts’ intuition and knack. Such management methods are detrimental to operational efficiency.

In contrast, Bridges@ny acquires GPS data from the driver's smartphone in real time. The service displays current locations of all running trucks on the map.

The visualization of the delivery progress makes the analog check of truck locations unnecessary, thereby lessening the operational burdens on the management staff.

In addition, smoother logistics can be achieved with Bridges@ny. This service enables identification and intervention for trucks that are likely to be affected by road traffic control. In addition, the cause of the delay can be investigated, resulting in prevention of recurrence and other improvements in business operations.

Optimal delivery route derived from quantum computer simulation

Optimal route planning is delivery routing that moves the maximum load by the shortest route, with the minimum number of trucks. Optimal route planning essential for improving delivery efficiency and reducing CO2 emissions, but it is an extremely difficult task to achieve due to the amount of available data.

For example, Aisin has more than 1,000 customers in Japan. For our plants in the Mikawa area alone, where our head office is located, the number of combinations of delivery routes is astronomical - a single-digit number followed by 25 zeros. It is said that the number of stars in the galaxy is about 1,000 trillion (15 zeros). Therefore, the number of route combinations can be described as "more than the number of stars.”

Meanwhile, order fulfillment and delivery are also complicated. Aisin handles more than 15,000 types of parts of different sizes and weights, whereby the weight and volume of freight vary depending on the type and number of parts transported. At a delivery destination, in addition to unloading, it is also necessary to collect used containers. While taking that load into account, we are also required to flexibly respond to varied requests from delivery destinations, such as delivery in a specified order.

In such complicated conditions, optimal route planning must derive the optimum solution from an enormous number of combinations. The required amount of computation goes far beyond the capabilities of conventional computers.

In collaboration with the startup “QC Ware”, Aisin has developed a formula to determine the optimal route that meets complicated conditions from a huge number of combinations. The use of a quantum computer, which is said to have a computing power 100 million times higher than that of a conventional computer, has made us confident that we can create a technology that automatically determines the optimal route. The creation of this technology will enable instantaneous delivery routing, which currently takes multiple persons about one month to calculate, thereby greatly helping increase operational efficiency.

Optimal delivery route derived from quantum computer simulation

Through these initiatives, we will achieve a high level of optimization of truck transportation and halve CO2 emissions from truck transportation by 2030.

Moreover, in the future, we will provide services using this technology also for other companies with similar issues to support transportation of more freight with less manpower. By doing so, we hope to contribute to the improvement of drivers’ working environment and the settlement of other logistics issues.

Part 2 covers two more projects for DX-L that aim to help achieve carbon neutrality and solve logistics issues.