Stopping is Just the Start of what These Brakes Can Do

~Cooperative Regenerative Brakes Contribute to Higher Fuel Efficiency and Increased Comfort~

Jul.28, 2022

What are cooperative regenerative brakes?

A quarter of a century has passed since Toyota launched the first-generation Prius. Today, it’s common to see battery electric vehicles (BEVs) and now hybrid electric vehicles (HEVs) everywhere. Internal combustion engines are still the major source of power for automobiles, but the proportion of the market that prefers electrically powered motor vehicles including HEVs and BEVs is undoubtedly on the rise.

The shift to electrification has made terms like “regeneration” and products like regenerative brakes more common than before, but the workings of these systems may still be unfamiliar to the general public. Here we will explore the basic mechanism of regenerative brakes.

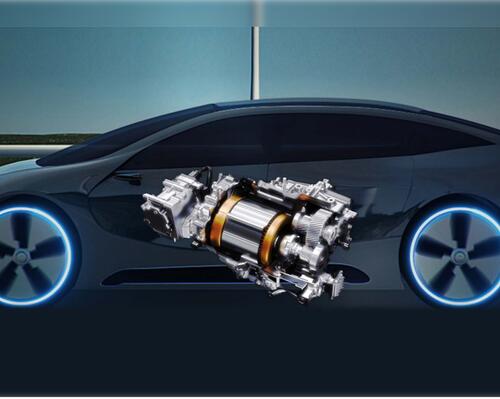

When supplied with electric power, a motor exerts torque to move the car. In contrast, when torque is applied to the motor as the car slows, electric power is generated. The motor functioning as a generator is the significant and primary difference between it and the engine which uses fuel to propel the car.

When the driver of an engine-powered vehicle eases up on the accelerator and the engine brake is applied, the vehicle slows. So does an electrically powered vehicle with a motor due to rotational resistance. During deceleration, an engine can stop consuming fuel but cannot produce gasoline to replenish the tank. Conversely, a motor can use the power-generation function to recover electricity. This is how regenerative brakes work.

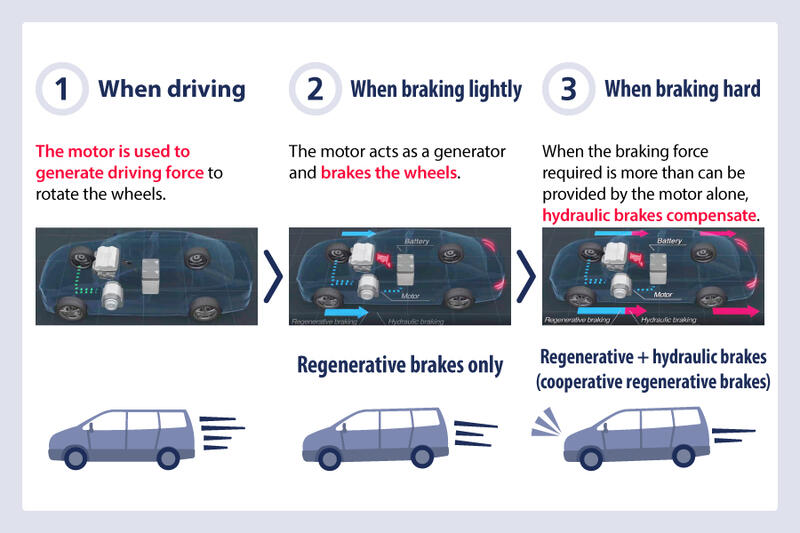

With the regenerative system as its foundation, we can begin to understand the “smart” control system that comprises cooperative regenerative brakes. When the four wheels of a car are equipped with mechanical (hydraulic) and regenerative brakes, the system automatically uses the correct brakes depending on the situation and coordinates them in a highly controlled way to recover as much electrical energy as possible.

When the driver steps on the brake pedal, this system determines how much braking force is required, and optimally allocates braking force to the hydraulic and regenerative brakes. This optimal allocation increases the amount of battery electricity available for driving, improving fuel efficiency/electric mileage and contributing to a considerable reduction in energy consumption. The reduced use of mechanical brakes’ frictional resistance also reduces wear on disc pads and the resulting brake dust and maintenance costs.

ADVICS’ industry-leading cooperative regenerative brake system

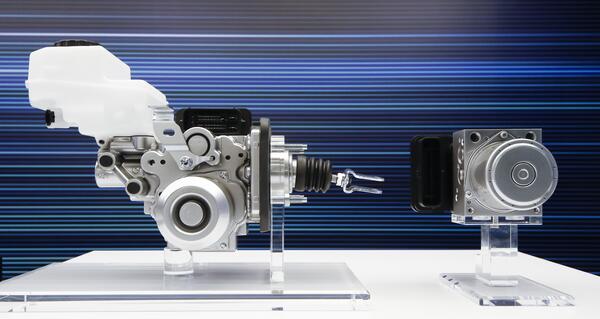

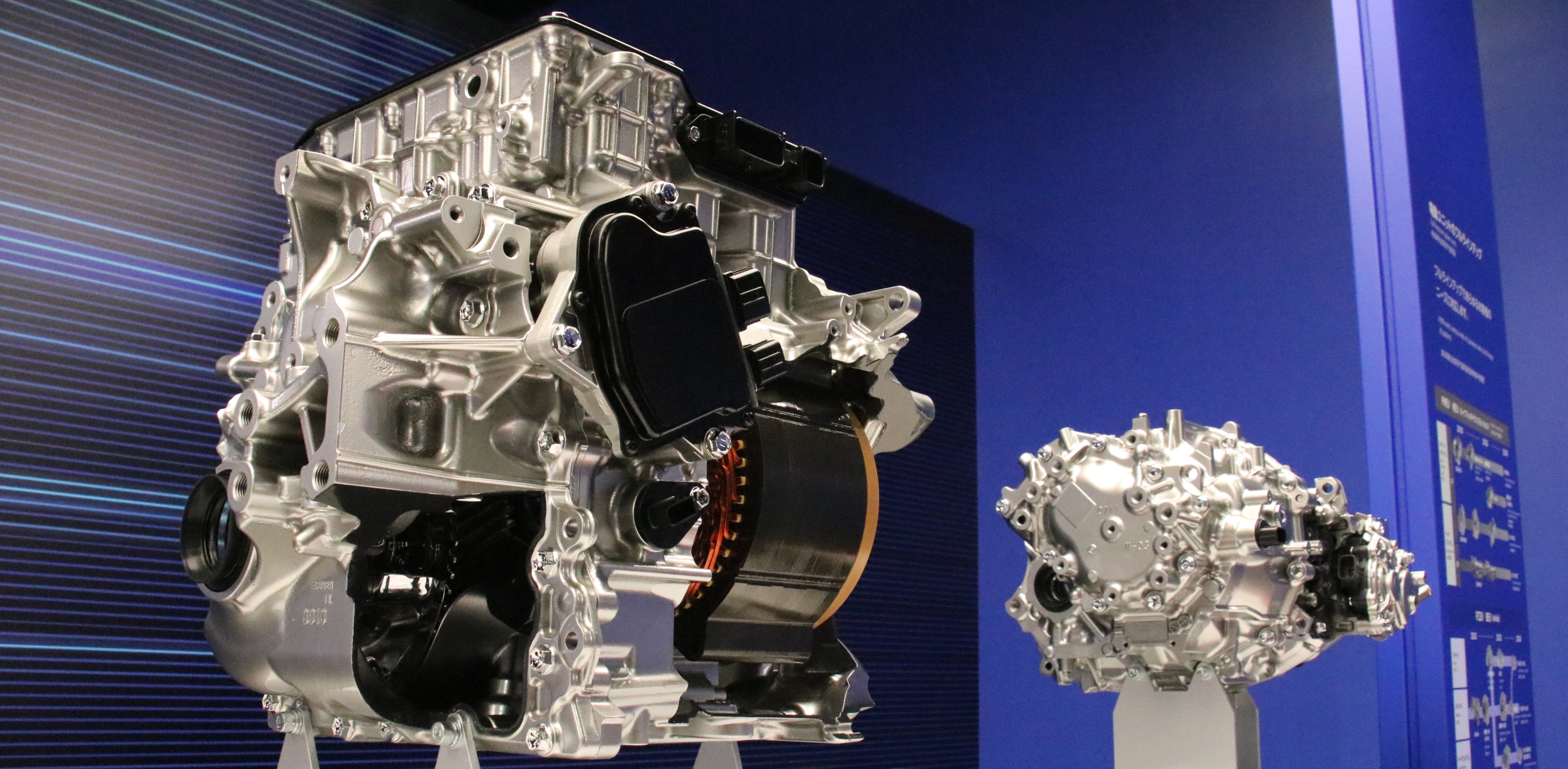

An electronically controlled brake system (left) and an ESC* modulator (right), which are components of the latest cooperative regenerative brake system developed by ADVICS.

ADVICS is a Tier One global brake system supplier established in 2001 as an Aisin Group company by integrating the brake divisions of Aisin, Denso, Sumitomo Electric Industries, and Toyota Motor Corporation.

It is worth noting that the much-talked-about Toyota bZ4X BEV, which became available for leasing in May 2022, is equipped with an ADVICS system. The automotive industry is in a period of great change, and carbon neutrality and the elimination of fatal accidents involving vehicles have become primary objectives. An increasing emphasis has been placed on the industry’s technological capabilities in meeting the needs for electrification, including autonomous driving, which is a technology close to practical use.

ADVICS integrates hardware with software technologies into brake products and produces these products as systems. Taking advantage of its extensive track record of producing cooperative regenerative brakes for HEVs, ADVICS offers a vast selection of high-efficiency and high-precision products for vehicles of various sizes.

* An electronic stability control (ESC) is an anti-skid device.

Stable vehicle posture due to individual control of front and rear brakes

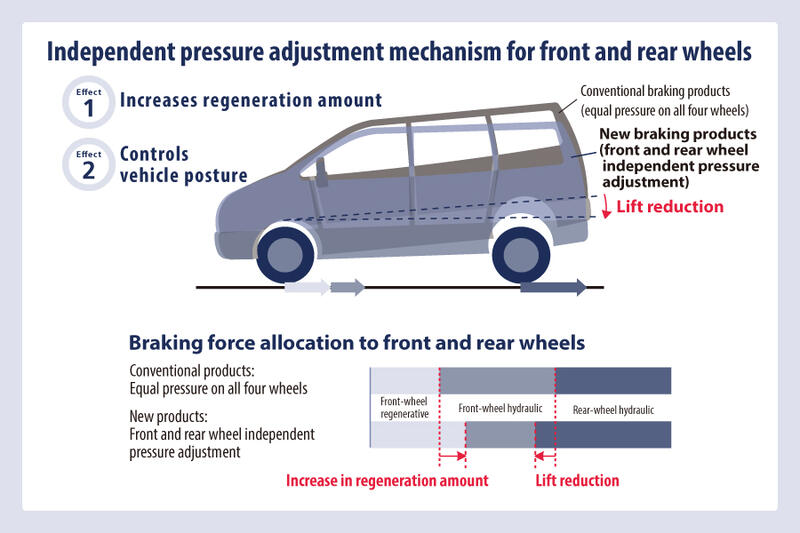

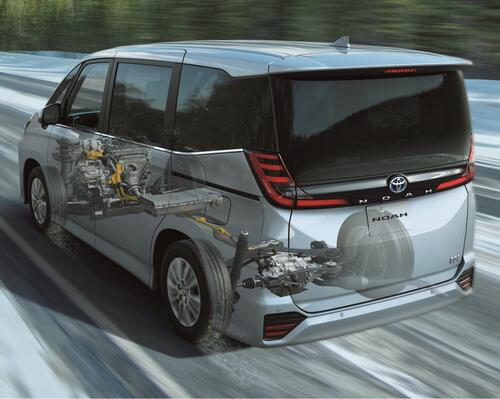

Engineers at ADVICS sought a way to recover more electric power with regenerative brakes without affecting the comfort of a smooth braking experience. Their continuous research and development for increased levels of efficiency has led to independent control of the front and rear wheel brakes like those in the bZ4X.

Unlike conventional products, which generate an equal braking force on each of the four wheels, the new products feature a control system for electronically controlled hydraulic brakes that is divided between the front and rear wheels.

The illustration above is an easy-to-understand representation of the mechanism for a front wheel drive vehicle. When the driver steps on the brakes to stop the car, the individual control of front and rear wheel brakes reduces the front-wheel hydraulic pressure to rely more on regeneration. Moreover, it increases the rear-wheel hydraulic pressure to suppress the lift of the rear of the vehicle body.

These effects collectively increase the use of the regenerative brakes, improving fuel efficiency and electric mileage compared with the conventional system.ADVICS’ efforts to enhance energy recovery efficiency have come to fruition by using energy to propel a car to even higher levels.

Furthermore, as shown in the illustration, the independent control also contributes to a stable vehicle posture when the car slows down and comes to a stop. A more stable posture means a more comfortable ride.

“Nameraka Brake” makes for a smooth ride for all drivers

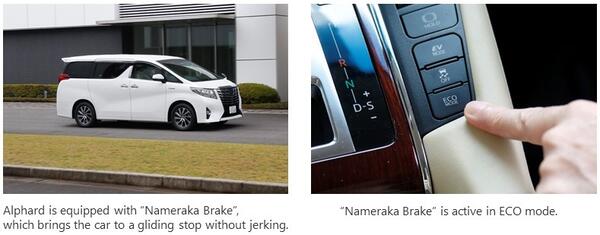

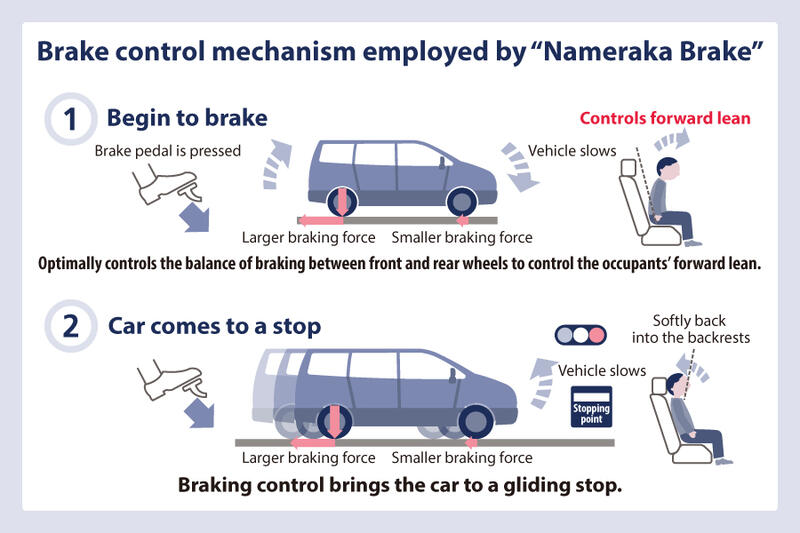

The system for independent control of front and rear wheel brakes also contributes to “Nameraka Brake (smooth braking system)”, an application provided by Kinto Factory, a service from the Toyota Group.

See the illustration below. When a driver stops the car, he or she steps on the brake pedal. When the brakes are applied the front of the vehicle body sinks due to deceleration, leaning the occupants forward.After that, the compressed suspension returns to its original height, which tends to unpleasantly jerk the occupants back into their seats.

A solution to this problem is the use of the independent control of front and rear wheel brakes and “Nameraka Brake”. With this newly-developed function by ADVICS and its proprietary software, when the car is brought to a stop, the braking force is allocated more appropriately to the front and rear wheels to suppress changes in the posture angle. Consideration is also given to the way the braking force is released when the car stops, enabling smooth and comfortable braking.

Kinto Factory-supported types of vehicles can be retrofitted with “Nameraka Brake” simply by rewriting the software installed on the car. This must-have technology should soon be widely available so drivers of all skill levels can provide a smooth, comfortable ride to their passengers.

Aisin has a vast range of electrification technologies and develops a wide variety of products that contribute to increased overall vehicle efficiency and energy saving. These products range from the brake-related products mentioned here to electric units such as the famous eAxle, thermal management systems for maximizing the performance of motors and batteries, and products for reduction in body weight and air resistance.

Aisin will continue to contribute to the evolution of mobility, while providing the global population with inspirational “movement” experiences.