Aisin eAxle evolves in pursuit of high efficiency and downsizing

~ Aisin’s latest initiatives for eAxle with an eye toward 2030 ~

Mar.31, 2022

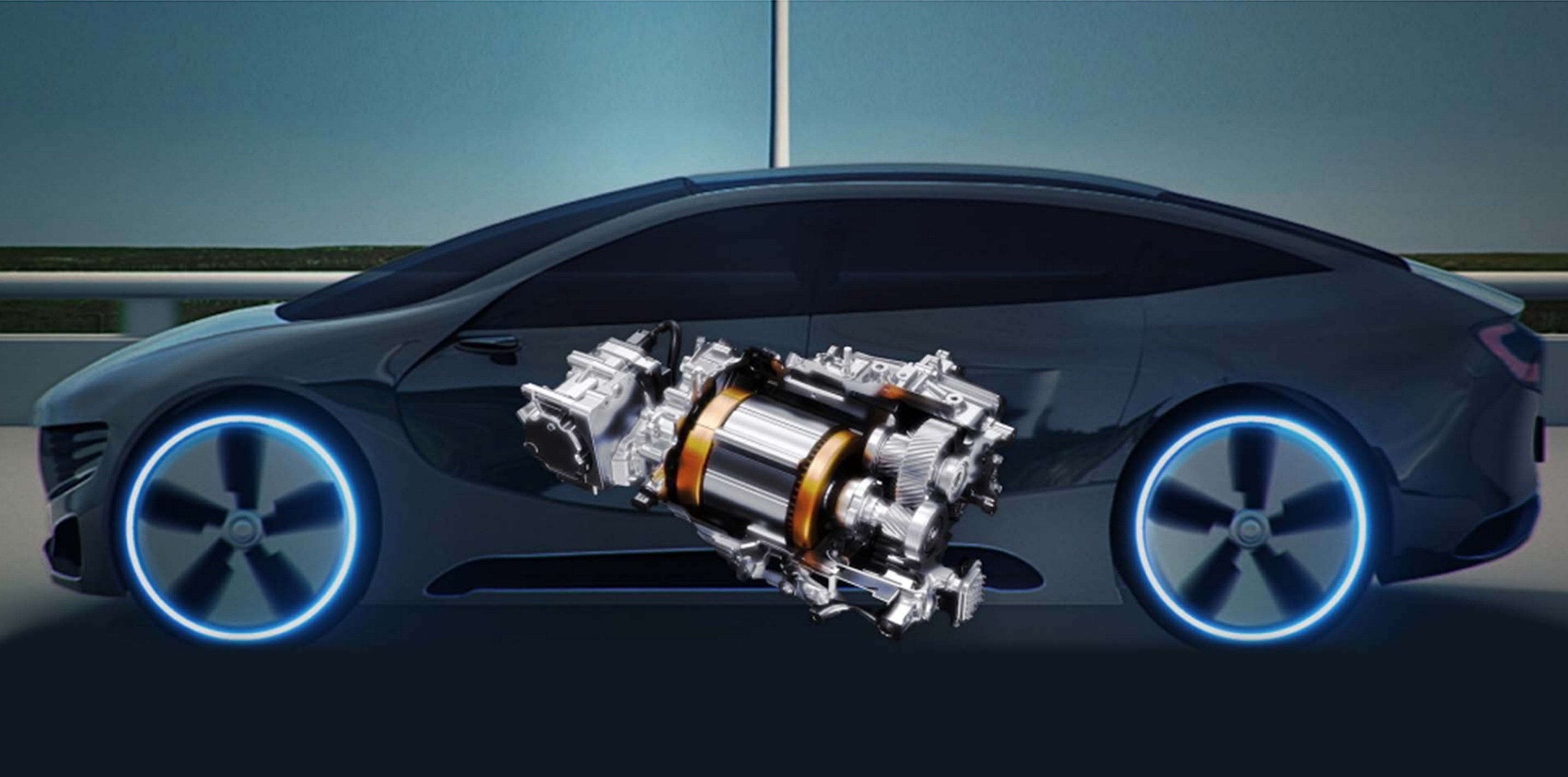

In the active global pursuit of achieving carbon neutrality, one of the most remarkable new products in the automotive industry is the eAxlewhich functions as the engine of conventional gas-powered vehicles, and is seen as the heart of battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs).

Aisin has been on the leading edge of eAxle development, and far ahead of our competitors. In 2019, we partnered with Denso Corporation to launch BluE Nexus Corporation, a new company dedicated to developing, adapting and selling eAxle.

In 2020, we commenced mass production of eAxle. However, the ever-expanding eAxle business has been attracting many suppliers, sharpening market competition.

How will Aisin take advantage of its strengths to move forward? And how will Aisin continue to impact carbon neutrality? Read on for our latest initiatives.

Developing 3rd-generation eAxle by converting a broad range of knowledge into new technology

As part of efforts to achieve carbon neutrality, we have been accelerating the electrification of vehicles by taking advantage of our historically developed products, expertise and processes. To promptly respond to the needs of our customers around the world, we strive to provide drive units for all types of vehicles, including hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), BEVs and FCEVs.

We see eAxle for BEVs and FCEVs as a key strategic product. Aisin is working on the development of the third-generation eAxle, which features incredibly high efficiency but at a much smaller size.

In the “Large Premium” line all the way to the right, the points should be bulleted if they are separate, driving should be lowercase. If they are all one line, driving should be lowercase as should “for”.

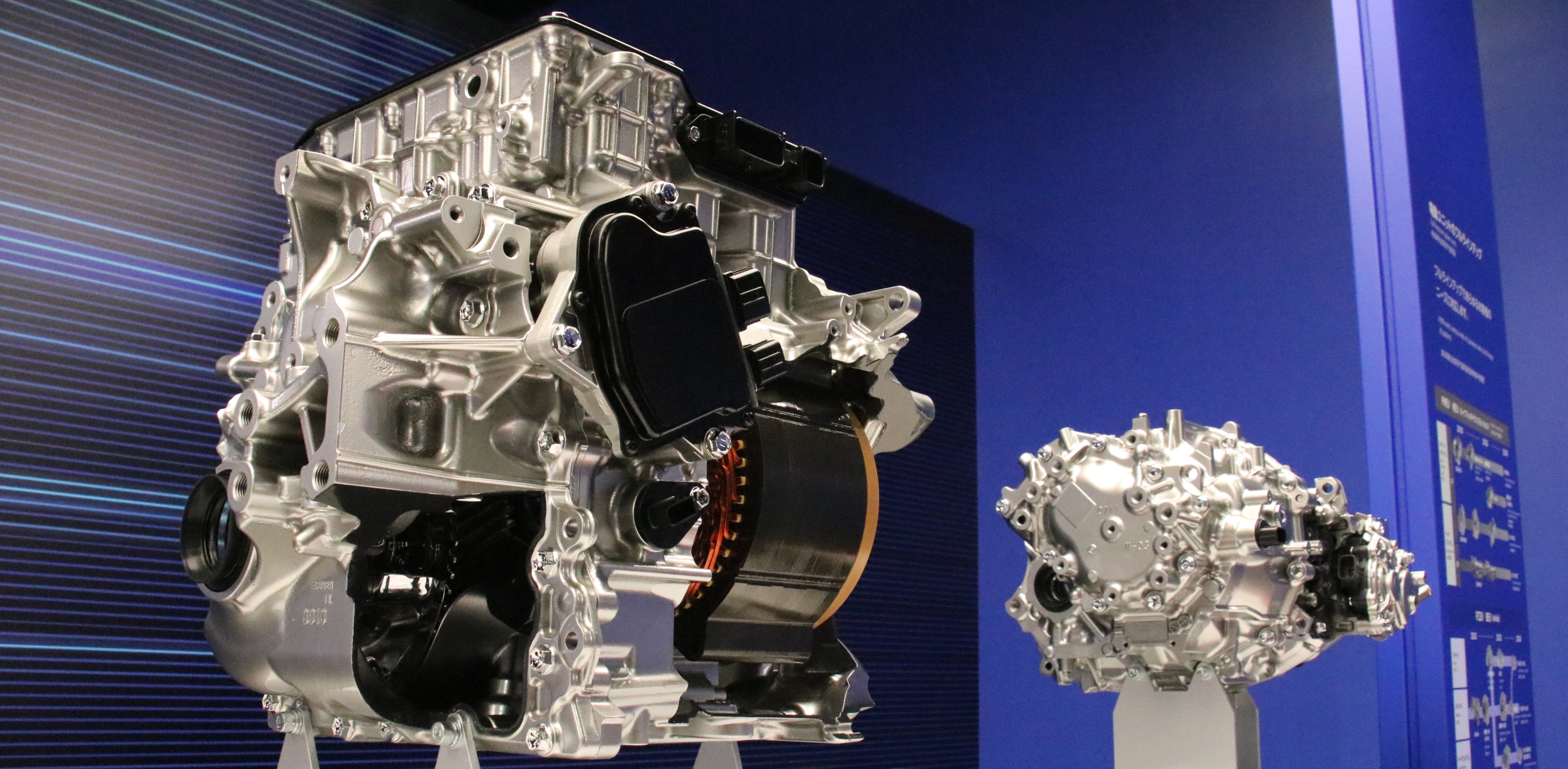

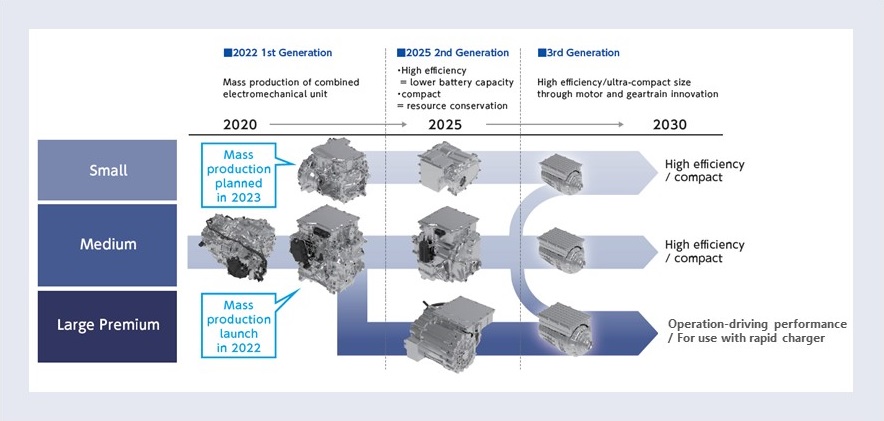

In 2022, we will start the mass production of a combined electromechanical unit, which is an integrated combination of gears or motors and electronic control circuits (inverters), as the first-generation eAxle.

We will offer a compact eAxle model for both the front and rear developed by employing the technology cultivated through the development of HEV transmissions. This will be followed by the mass production of products for small cars.

In 2025, during an expected rapid increase in demand for BEVs, we are planning to launch a small, medium and large eAxle, realizing both high efficiency and compact size, as the second generation.

In second generation products, we seek to reduce the total energy consumption of a vehicle (equivalent to the power consumption ratio or fuel efficiency of gas-powered vehicles) by 10% or more from that of the first generation. This means enabling the battery capacity to be lowered by 10%. These seemingly small improvements provide vehicle users with many benefits. For example, improved electric mileage can lead to expanding the driving range, and a smaller battery can lead to more vehicle interior space.

We will accelerate our efforts toward the development of the third generation.

Aisin can boldly take on these new challenges because of the extensive knowledge and expertise we have accumulated over many years as a global manufacturer leader in the automobile industry. We seek to develop an unprecedented type of eAxle by utilizing gear, shaft, casing and other technologies cultivated through the development of the automatic transmission (AT) and by strengthening collaboration with outside organizations.

Establishing a global system to flexibly respond to changes, with an eye toward 2030

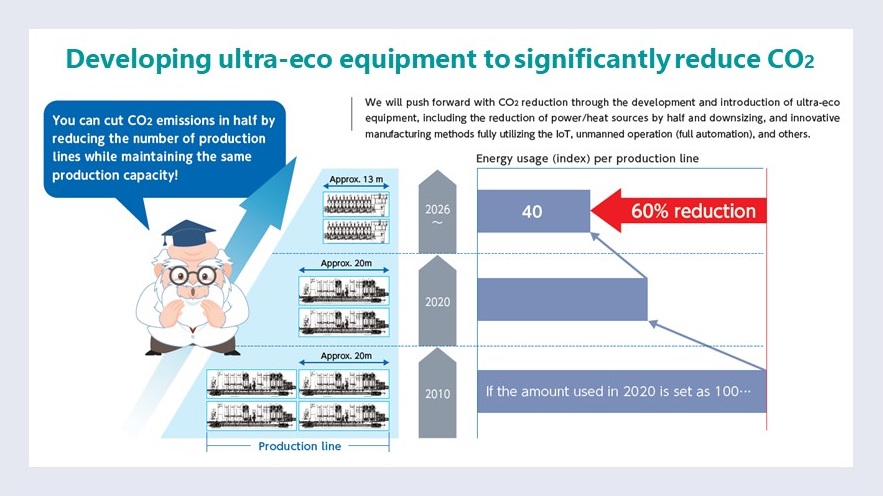

With regard to our efforts in terms of production to achieve carbon neutrality, we have several ways we will reduce CO2 emissions in our production processes: by converting the existing AT production facilities into production of electrification products, halving the number of production lines, promoting unmanned operation of production lines, and introducing a common platform to respond to a wide variety of products. In addition to new investments, we will use the existing facilities to establish a global production system that can flexibly respond to future technologies and their needs.

Our human resources represent our future potential to promote electrification. We have recently relocated about 1,500 engineers from development and production technology departments to electrification-related departments, and with these talented and dedicated minds shaping our technical capabilities, we are best equipped for the electrified future.

Our goal is to contribute to the popularization of electric vehicles and achieve carbon neutrality in various processes from the provision, production and disposal of products related to electric vehicles.

Our mission is to touch the future of mobility in a way that is exciting, impactful and accessible to all, and we will deliver on that by offering electrification products made by our highly cultivated, leading-edge technology.