What is "carbon dioxide fixation" and why should we care?

Jun.14, 2024

It’s no secret that average global temperatures rise every year and are caused by several contributing factors. For example, carbon dioxide (CO2), which is considered a threat to the global environment, is most accountable and has the greatest negative impact.

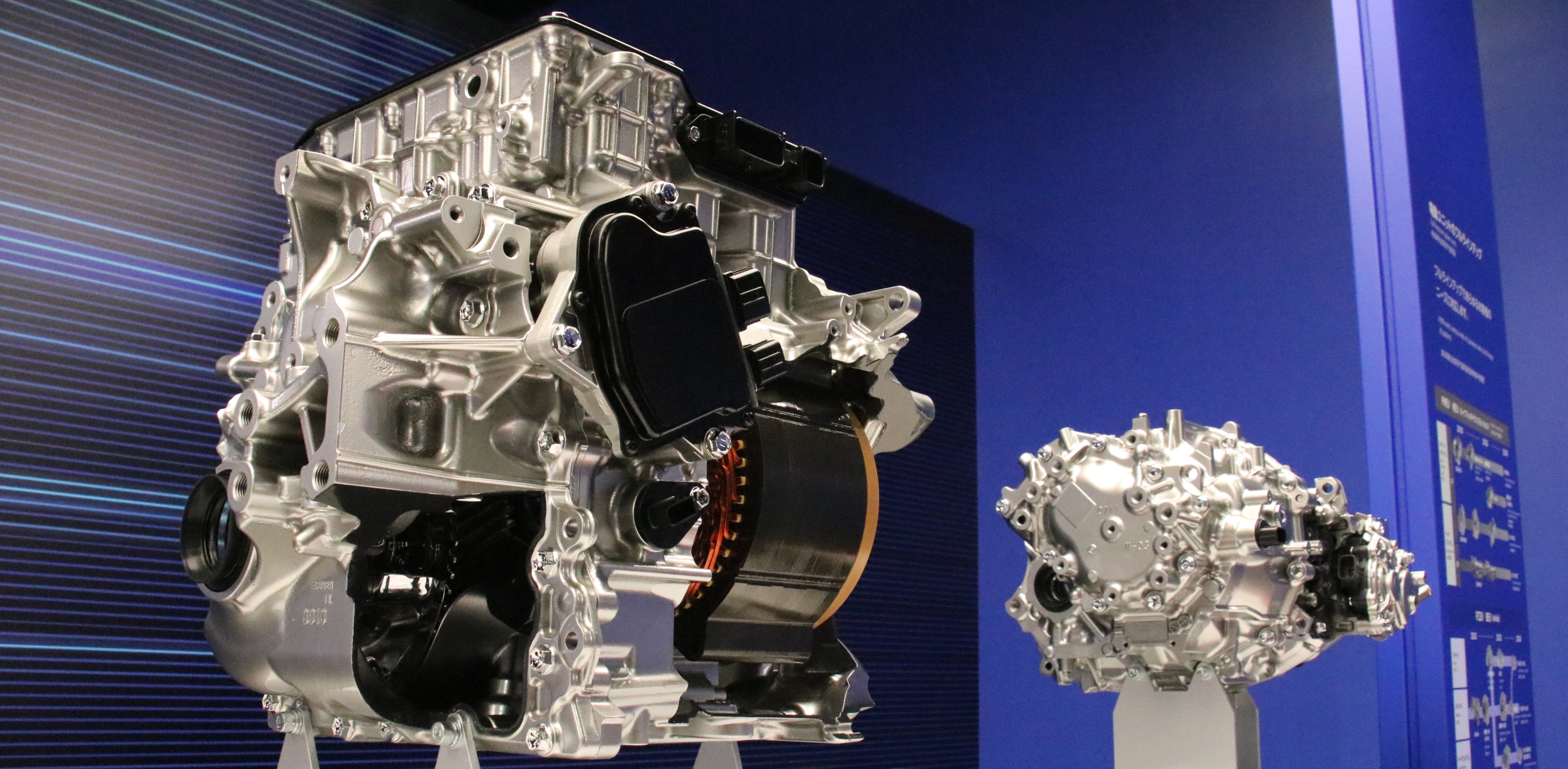

Today, despite worldwide efforts, CO2 is increasing because of day-to-day living and industrial activities. And, because AISIN emits a large amount of CO2 during the manufacturing process of automotive parts, the company has been diligently working to reduce its CO2 emissions to help improve quality of life and a sustainable global environment.

Help is on the way

Fortunately, there are initiatives to help reduce CO2, among them: Carbon fixation technology, a biosynthetic pathway that converts atmospheric carbon into metabolically active organic compounds. This process means CO2 can be converted into calcium carbonate and used as a material for concrete and resin, making it possible to effectively use it in a wide range of applications, including structures such as bridges and tunnels, and even automobile parts.

CO2 fixation is beginning to attract attention worldwide as a promising technology for achieving carbon neutrality (CN), which means reducing CO2 emissions virtually to zero. AISIN is rapidly advancing development of the technology, aiming for plant demonstration in 2026 and practical application around 2030.

CO2 fixation is an effort to fix gaseous CO2 in some form to reduce the amount of CO2 released into the atmosphere. The most familiar example is photosynthesis, which takes place in nature. Plants absorb CO2 during the process of photosynthesis and store it as carbon. Storing (fixing) CO2 inside plants reduces the amount released into the atmosphere.

Making good use of the bad CO2

AISIN first began its efforts to artificially fix CO2 more than 15 years ago. The project started in 2008 as advance development of production technology. At the time, CN had not yet become a hot topic, and global warming was not recognized as a major problem affecting all of humanity as it is today.

Yoshiki Wakimoto, who has been involved in the project since the beginning of the development, takes a look back on that time:

“At AISIN, we were aware that the die-casting process, in which iron and aluminum are melted and molded, emits large amounts of CO2, so reducing CO2 emissions had already become a company-wide management issue,” says Wakimoto. “The development staff were enthusiastic, thinking, ‘Maybe there’s a way to actually put CO2, which has been blamed, to good use.’”

“The technology that caught their attention was one used to react CO2 with calcium to produce calcium carbonate for fixation,” adds Wakimoto. “When slag from steel mills or waste concrete powder from the cement industry is added to water or other liquids, calcium dissolves from the raw material. Calcium carbonate is produced by blowing CO2 emitted from our factory into this solution. The idea is to fix CO2 as calcium carbonate and utilize it.

“The most common way to extract calcium is to dissolve it in water. However, if we are to aim for commercialization, we will need processing capacity in the tons in the future. Using water would be inefficient and impractical,” he says.

Wakimoto and his colleagues quickly gave up and began looking for an alternative solution and they gazed into their beakers day-after-day.

“This technology is one of the important options for achieving significant reductions in CO2 emissions. We wanted to make good use of it, so we gathered over 50 different ingredients, combining them one by one, and tested their reactions,” said Wakimoto.

In 2011 a collective “Wow!” rang out through the laboratory. The special amino acid solution Wakimoto and his team finally discovered produced very little CO2 bubbles upon injection, indicating that the CO2was being absorbed very efficiently.

Achieving 10 times more efficiency and economical advantages

This special amino acid solution can fix CO2 more than 10 times more efficiently than if the material were dissolved in water. Another feature is that it is easy to handle as it does not require complex temperature control or chemical processing. In addition, amino acids are originally substances that constitute the proteins that make up the bodies of living organisms and are also widely available as food, so their safety was also a deciding factor.

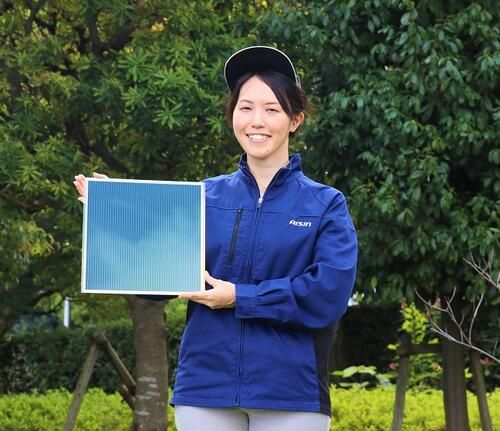

The used amino acid aqueous solution can be filtered and reused many times, making it economically advantageous. AISIN has obtained a patent for technology that is designed to extract calcium using an amino acid aqueous solution and bind it with CO2.

But then, in 2019, the project was put on hold.

“We couldn’t find a use for the calcium carbonate we produced, so it was difficult to come up with an exit strategy,” says Wakimoto about the reason. He added: “To contribute to the environment, the amount of CO2 trapped must exceed the amount of CO2 released during the calcium carbonate production process. Improving this CO2 balance became a big hurdle.”

A new hope for the technology developed over 15 years as development is accelerated, thanks to new members

The development ceased to progress. But in 2021, the project gained momentum again. Joint development began as Taisei Corporation, which was focused on the development of

T-eConcrete®, environmentally friendly carbon-recycled concrete, took notice of AISIN’s CO2 fixation technology. The growing global momentum towards realizing CN also provided a tailwind.

“It’s rewarding to work on technology development when we have a clear goal. Morale of the development staff also rose dramatically,” said an enthusiastic Masafumi Akamatsu, who is leading the project, and adds that in addition to younger employees who actively volunteered in response to internal job postings, talent was also attracted from various departments and group companies.

“We also have experts in equipment and analysis. Whenever a problem is found, someone with more knowledge would quickly make improvements, creating an environment where the improvement can be put to good use next time,” said Akamatsu.

Thanks to this synergistic effect of human resources, the development progressed at an accelerated pace.

A demonstration at the Nishio Die-Casting Plant studies a practical application

The project is currently continuing with experiments on a bench-scale plant with a processing capacity of two tons of CO2 equivalent per year. The plan is to get a sense of the technology here and then build a demonstration facility 100 times larger within the die-casting plant by the end of fiscal 2025. A demonstration stage of the plant will begin with a view to practical application, utilizing the CO2 contained in exhaust gas from aluminum melting furnaces.

Toward large-scale production, the plan is to go beyond simply improving equipment and processes and to pursue more in-depth research and development.

Bringing beauty to our future Earth with CO2 fixation technology

The first step in using the calcium carbonate produced will be to develop concrete in collaboration with Taisei Corporation. Using it in automobile parts in the future is also envisioned.

“Although the technical hurdles are high, it could potentially be used as a material to increase the volume of paints and resin materials,” said Akamatsu. “CO2 fixation is an attractive technology that can be deployed in a wide range of fields and contribute to the environment. I want to raise awareness of the technology by first putting what we can out there.”

However, Wakimoto, who recalls the disappointment when the project was previously put on hold, added: “I will never forget the frustration I felt when the project came to a halt. Now, I am determined to make this work and make it practical and contribute to society. We will develop CO2 fixation into AISIN’s representative environmental technology, which will bring beauty to our future Earth.”

We are entering an era in which efforts toward carbon neutrality will determine a company’s competitiveness. AISIN is working on CN in terms of both products and production, with the goal of achieving production CN by the end of 2030. CO2 fixation technology is not only an important key to achieving this goal but also holds the potential to open new business fields. AISIN will continue to accelerate research and development as it relates to this technology.